Why Pick Specialist Welding Inspection Madison for Your Jobs

Why Pick Specialist Welding Inspection Madison for Your Jobs

Blog Article

Recognizing the Basics of Welding Examination to Ensure High Quality and Safety And Security

In the world of modern-day engineering, welding assessment stands as a foundation for making sure both the high quality and safety of structural productions. The procedure entails a thorough evaluation of welded joints, using advanced methods such as ultrasonic and radiographic screening to discover surprise blemishes. The know-how of certified inspectors is important, as they link the space between theoretical standards and practical application. Their duty prolongs beyond mere detection, incorporating the paperwork and interaction of findings to relevant stakeholders. What are the nuances of these inspection methods that make them important for maintaining structural integrity?

Relevance of Welding Examination

In the world of commercial construction, the relevance of welding inspection can not be overemphasized. Welding examination plays an essential role in making sure the stability, safety and security, and longevity of bonded frameworks. Provided the varied applications of welding in sectors such as building and construction, automobile, aerospace, and shipbuilding, the demand for strict quality control steps is critical. Correct assessment makes certain that welds satisfy specified requirements and codes, which is essential for preventing structural failures that could cause tragic repercussions.

The procedure of welding inherently involves complex variables, including temperature level, material buildings, and ecological problems, all of which can affect the quality of the weld. A complete evaluation recognizes issues such as cracks, porosity, and incomplete combination, which can compromise the strength and dependability of the weld. By detecting these concerns early, rehabilitative activities can be taken, thereby minimizing the danger of failure and associated expenses.

In addition, welding evaluation contributes to regulative compliance, as numerous industries are regulated by rigorous safety and security standards and standards. Failing to stick to these regulations can result in lawful liabilities and economic fines. Inevitably, welding inspection not only safeguards physical structures however likewise secures human lives and promotes sector online reputations.

Key Welding Assessment Techniques

Although welding inspection is vital to guaranteeing the quality and safety and security of bonded frameworks, it is the specific methods utilized that establish the performance of the assessment procedure. Key welding inspection techniques can be broadly categorized into non-destructive testing (NDT) and devastating screening. Non-destructive screening approaches such as visual examination, ultrasonic testing, radiographic screening, magnetic bit screening, and fluid penetrant screening are mostly made use of to examine the residential properties of a weld without causing damages. Visual inspection is frequently the primary step, including a complete evaluation of the weld's surface for issues like splits or porosity.

Magnetic fragment testing and fluid penetrant screening are surface examination techniques used to find surface area and near-surface defects. These extensive inspection approaches make certain that welds meet market criteria and safety needs, therefore making sure architectural honesty and efficiency.

Role of Licensed Inspectors

Licensed assessors play an essential duty in the welding evaluation procedure, making sure that all welds abide with stringent market criteria and safety laws. Their expertise is essential in determining problems or abnormalities that may compromise the architectural honesty of a weld. By carefully checking out each weld, licensed inspectors help avoid potential failures that can result in harmful accidents or pricey repairs.

To helpful site come to be licensed, inspectors must go through extensive training and screening, which acquaints them with numerous welding techniques, materials, and screening approaches. This comprehensive knowledge allows them to assess weld top quality efficiently and make notified judgments concerning their safety and reliability. Additionally, certified assessors excel in interpreting specs and blueprints, making certain that the welding job straightens with the job's style demands.

An integral part of their duty is to record their findings completely, supplying a detailed record of the evaluation process. This paperwork is crucial for traceability and accountability, working as an official record of conformity with market standards. Licensed examiners also play a crucial function in helping with communication in between job stakeholders, offering recommendations and understandings to improve welding practices and end results. Their payment is indispensable in maintaining high degrees of high quality and security in welding operations.

Devices Used in Welding Evaluation

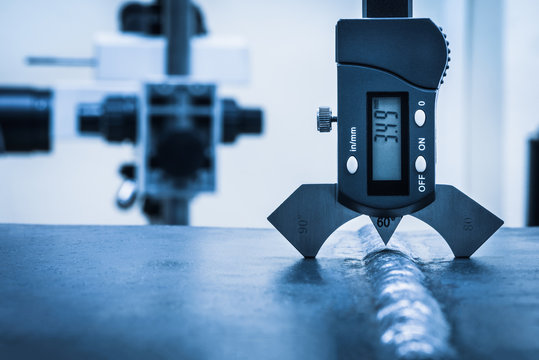

Welding examiners depend on a variety of specialized tools to perform their tasks efficiently, ensuring each weld fulfills the needed criteria. Among these devices, visual assessment help like amplifying glasses and mirrors are basic, permitting inspectors to very closely analyze welds for surface defects such as cracks, porosity, and undercut. Calipers and fillet weld assesses are vital for gauging weld measurements to verify conformity with layout specifications.

Advanced devices extend beyond aesthetic help, consisting of non-destructive screening (NDT) tools. Ultrasonic screening devices are critical in discovering subsurface problems, utilizing audio waves to reveal internal gaps without compromising the weld's integrity. Similarly, radiographic testing uses X-rays or gamma rays to capture photos of a weld's interior, highlighting potential issues.

Magnetic fragment screening is one more crucial device, specifically for identifying surface and near-surface interruptions in ferromagnetic materials. By applying electromagnetic fields and ferrous particles, assessors can determine defects that could or else be undetectable.

Dye penetrant evaluation is typically utilized for non-ferrous products, providing a contrast-enhanced visual look for surface-breaking defects. Welding Inspection Madison. Together, these devices make it possible for welding assessors to thoroughly analyze weld quality, making certain safety and security and reliability in numerous applications across industries

Ensuring Architectural Honesty

Welding procedures should stick to well established standards and codes, such as those defined by the American Welding Culture (AWS) or the International Company for Standardization (ISO) These standards make certain that the welds can stand up to functional stresses and environmental factors. Qualified and certified welders play a crucial duty in this procedure, as their knowledge makes certain that techniques are used appropriately, reducing issues such as cracks, porosity, and incomplete blend.

Post-weld examination is another vital element of confirming structural stability. These evaluations validate that the welds fulfill the needed high quality requirements, supplying guarantee of their longevity and integrity.

Final Thought

The principles of welding inspection are important for maintaining the high quality and security of bonded frameworks. The usage of specialized tools even more enhances the evaluation process, ultimately safeguarding human lives and lengthening the life-span of welded buildings.

Welding assessment plays an essential duty in making sure the honesty, safety and security, and longevity of bonded frameworks.Although welding examination is critical to guaranteeing the quality and security of welded structures, it is the details methods employed that figure out the effectiveness of the assessment process. Secret welding examination approaches can be generally categorized right into non-destructive screening (NDT) and damaging screening.Certified assessors play an essential more info here role in the welding assessment procedure, making certain that all welds abide with rigid industry requirements and safety and security policies.The principles of welding evaluation are crucial for keeping the high quality and security of welded frameworks.

Report this page